Design and Test Services

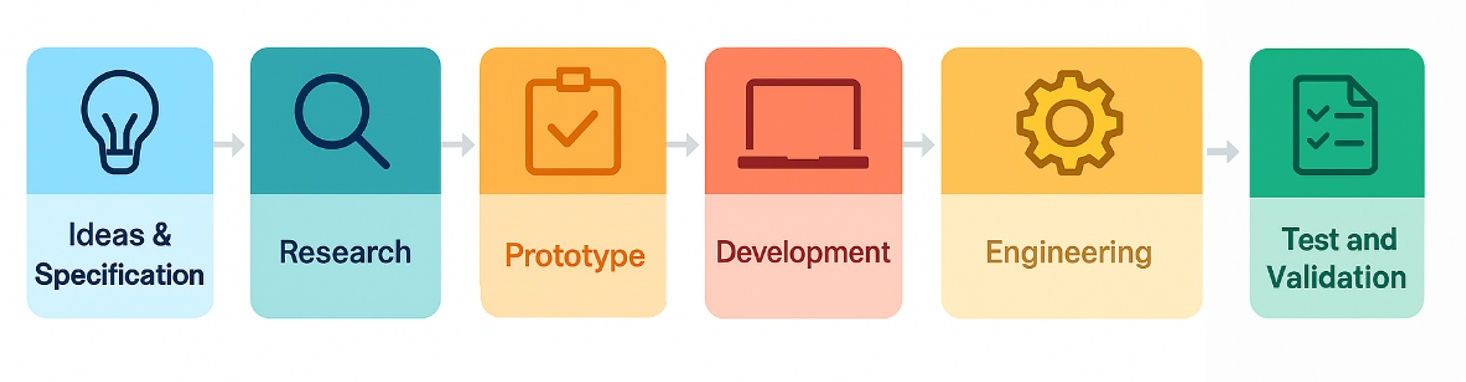

From Concept to Production, The Complete Design Process.

At the heart of every successful product is a well-engineered design. Our end-to-end product design services guide you from initial ideas through to a fully validated, manufacture-ready solution. Whether you’re creating a new product or device, enhancing an existing design, or solving a complex challenge, our team brings the technical depth and practical experience needed to deliver exceptional results. We handle projects of all sizes and offer flexible engagement models to suit your requirements.

Ideas & Specification:

Turning Ideas into Clear Requirements. Every successful product begins with a strong foundation, clear ideas and precise specifications. In electronic and product design, this stage is critical for aligning innovation with practicality. Our process ensures that your vision is transformed into actionable design requirements that guide the development journey.

What We Do at This Stage:

- Capture Ideas: We work closely with you to understand your concepts and goals.

- Define Specifications: Detailed specifications are created to outline functionality, performance targets, and compliance needs.

- Document Requirements: Comprehensive documentation ensures clarity for engineering teams and stakeholders, reducing ambiguity and risk.

- Set Targets: We establish measurable objectives for cost, performance, and timelines to keep the project on track.

- Understand Customer Requirements: By analysing user needs and market expectations, we ensure the product delivers real-world value.

This phase is where creativity meets structure. By combining technical insight with a deep understanding of customer requirements, we lay the groundwork for a design that is innovative, feasible, and ready for development.

Research

Effective product development begins with focused research that validates ideas before time and resources are invested. We explore market needs, customer pain points, competitor products, and emerging technologies to identify opportunities and reduce development risk. This includes assessing feasibility, reviewing relevant components and materials, and understanding how existing solutions perform.

With this insight, we define clear product requirements and highlight where your concept can truly stand out. The research phase ensures every decision—from technology selection to feature priorities—is grounded in evidence, setting a strong foundation for successful design and development.

Prototyping

Rapid Prototyping and Proof of Concept. Speed matters in product development. Our rapid prototyping capabilities allow you to quickly evaluate form, fit, and function before committing to full-scale production. By creating early models, we help you visualize your concept, identify design challenges, and make informed decisions without costly delays.

Why It’s Important:

- Validate Critical Assumptions: Before investing heavily in development, we ensure your concept works as intended.

- Reduce Risk: Early prototypes highlight potential issues, saving time and resources later.

- Accelerate Innovation: Rapid iterations mean faster feedback and quicker progress toward a market-ready product.

What We Deliver:

- Proof-of-Concept Models: Tangible samples that demonstrate core functionality and feasibility.

- Quick System Mockups: Using existing hardware and software, we build working models to prove your concept in real-world conditions.

- Flexible Prototyping Options: From simple mockups to advanced functional prototypes, tailored to your project needs.

This stage bridges creativity and engineering, ensuring your ideas are practical, scalable, and ready for development

Development

During the development phase, we transform research-driven insights into a fully engineered product. Using the findings gathered earlier, we refine the design, optimise functionality, and ensure the solution aligns with user needs, technical requirements, and manufacturing constraints. Every decision—materials, layout, component selection, and architecture—is guided by evidence to deliver a product that is both practical and commercially viable.

Our engineering team specialises in PCB design, embedded hardware development, outdoor enclosure design, and the integration of microcontrollers and microprocessors tailored to your product’s performance and power needs. We focus on robust electronics design, signal integrity, and system reliability while ensuring compliance with EMC and safety standards. This phase brings together mechanical, electrical, and firmware expertise to build a design that is ready for in depth testing.

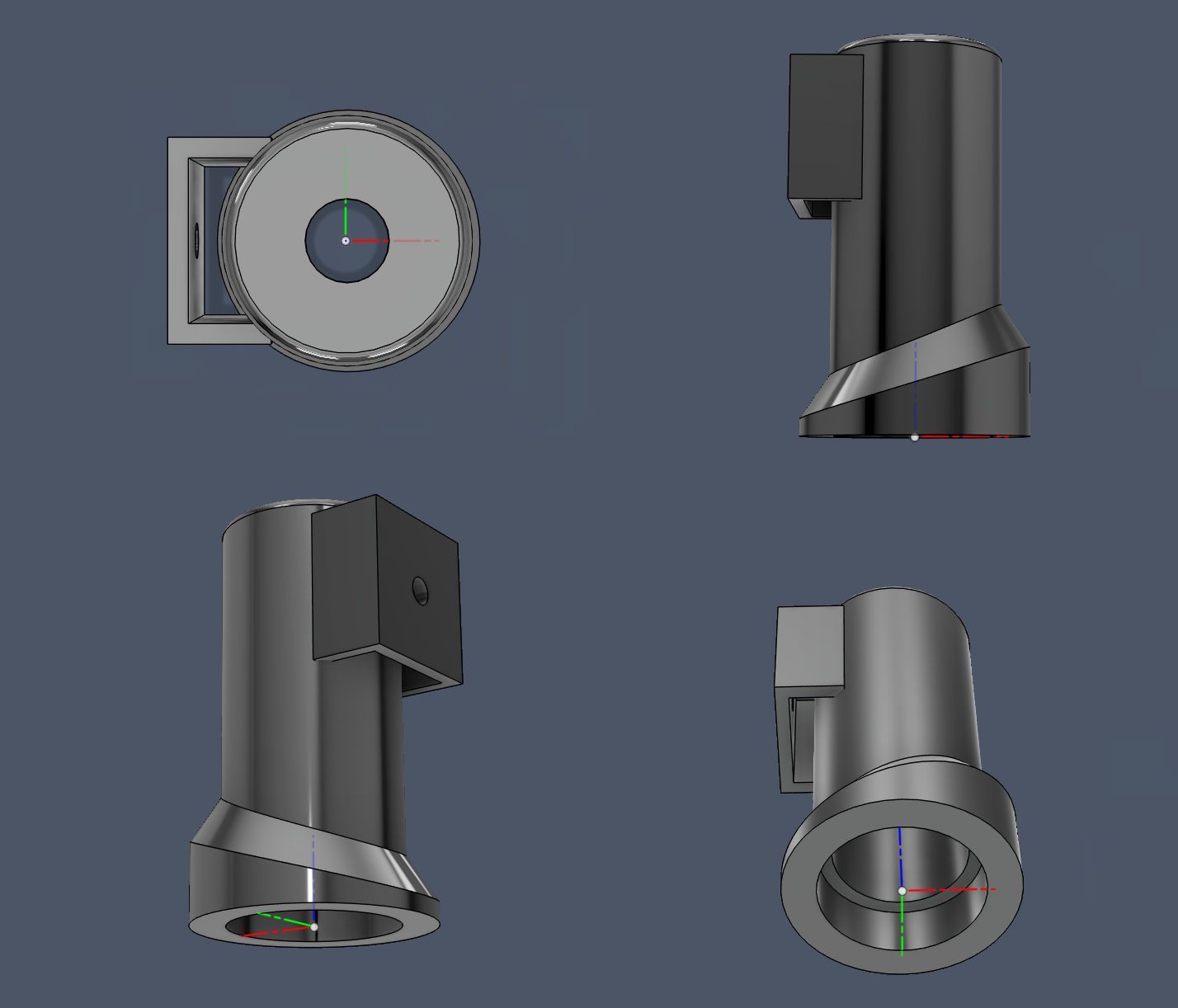

Engineering

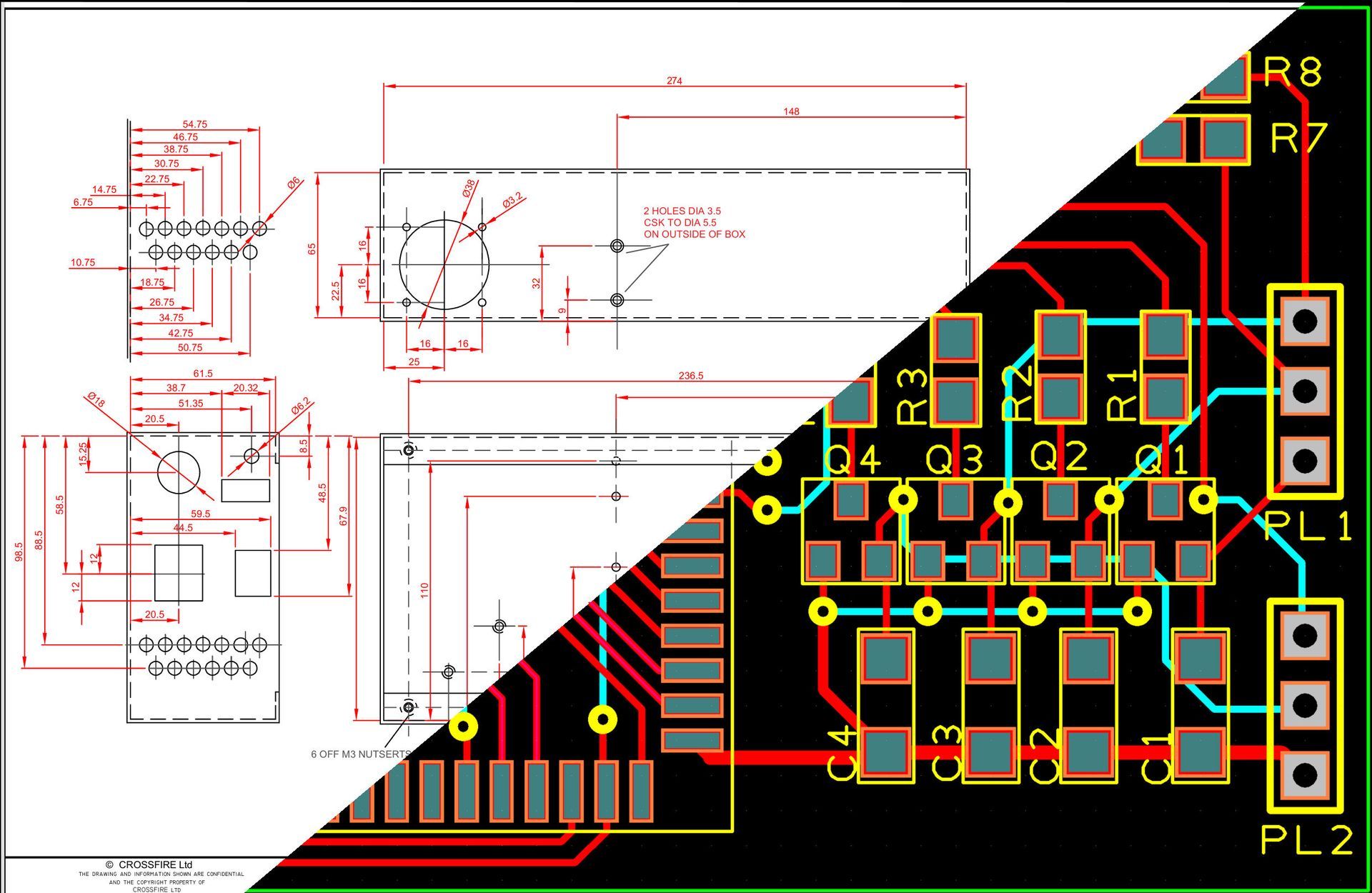

Engineering and Technical Drawings. A design must be well engineered to ensure it can be physically manufactured, we produce detailed technical drawings, and engineering specifications to ensure your product is built precisely to requirements.

This includes 2D manufacturing drawings, 3D CAD models, tolerance analysis, and mechanical design files optimized for production.

Test and Validation

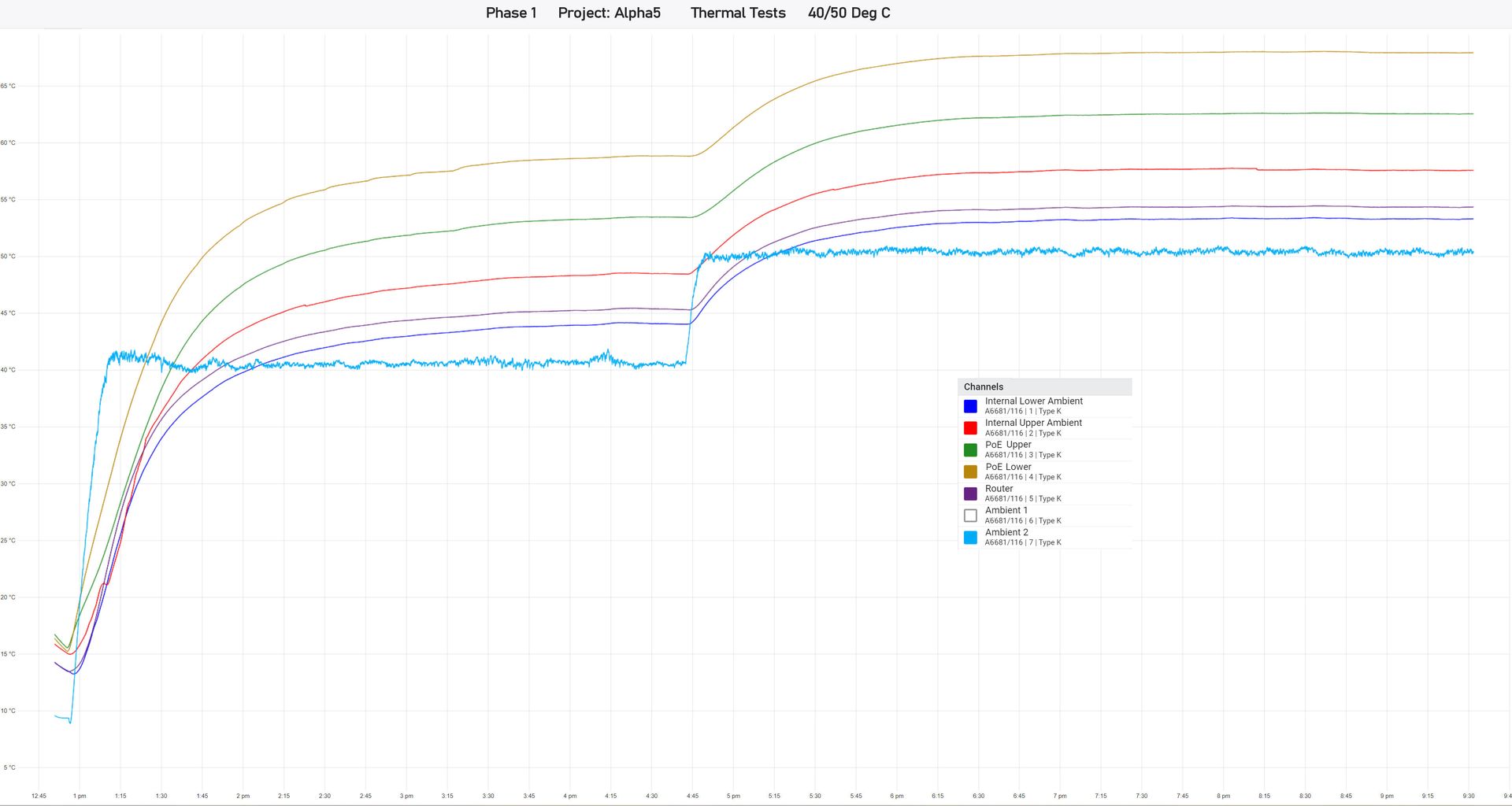

Environmental Testing & Verification. Real-world conditions demand real-world testing. We perform a wide range of environmental tests, many of which are done inhouse to validate durability, safety, and performance, this could include for example:

- Heat chamber testing.

- Water and dust ingress testing.

- Vibration, drop, and mechanical stress testing.

- Humidity and environmental exposure tests.

- Automated wear testing.

This ensures your product meets industry standards and performs reliably in its intended environment.

A word on documentation

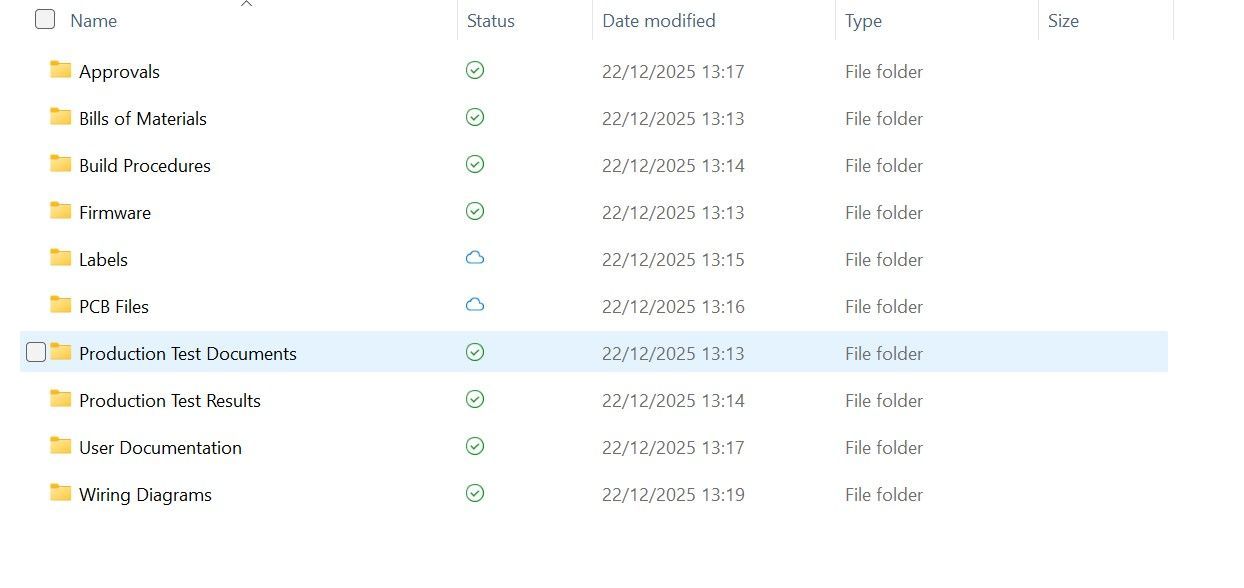

Documentation and Manufacturing Readiness

Thorough documentation is essential for turning a finished design into a repeatable, reliable product. We produce clear, structured engineering documents that capture every detail needed for manufacture, assembly, and testing. This includes a complete Bill of Materials (BOM) with component specifications, supplier information, and lifecycle considerations, ensuring cost transparency and supply-chain stability.

To support smooth production, we also generate detailed build and test procedures, assembly drawings, wiring diagrams, and quality-control checklists. These documents ensure that every unit can be built consistently, tested correctly, and validated to the required standards. By combining technical clarity with manufacturing best practice, we help ensure your product is ready for scale, certification, and dependable long-term production.

Testing

Testing Services

We offer a comprehensive suite of testing services designed to ensure your products meet the highest standards of quality, reliability, and compliance. These services can be seamlessly integrated into a complete product design project or delivered as standalone solutions, depending on your needs. Our testing capabilities include (but not limited to):

- Heat Chamber Testing: Evaluate product performance and durability under extreme temperature conditions to ensure thermal stability.

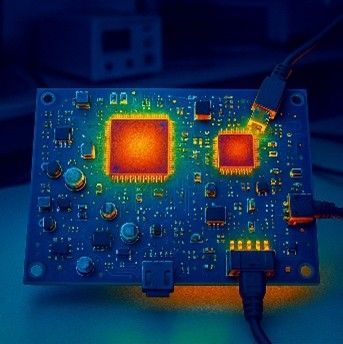

- Thermal Analysis: Using thermal imaging to detect hot spots and optimize heat dissipation. This ensures better cooling, improved reliability, and longer product life.

- RF Testing: Verify RF output levels and signal quality up to 6Ghz

- Range Testing: Assess the operational range of wireless devices to confirm reliable performance in real-world scenarios.

- Mechanical Testing: Vibration, drop, and stress tests to validate the physical robustness and durability of your product

- Design Verification: Systematically check that your product meets all design specifications and functional requirements.

- Post Production Testing: Inspect and test each manufactured unit to guarantee consistent quality and identify any defects prior to delivery.

- Stress and Wear Testing: Simulate long-term use to uncover potential failure points and ensure product longevity.

- Life Cycle Testing: This assesses the longevity and performance of components over time through accelerated aging processes.

- Burn-In Testing: Components are exposed to high temperatures and electrical stress to detect potential defects and ensure long-term reliability.

- Functional Testing: This verifies that a device operates according to its intended purpose by checking inputs, outputs, and operational modes.·

- Performance Testing: This evaluates the performance of electronic components or systems under specified conditions, including signal quality and power consumption assessments.

- Safety & EMC Testing: We manage and coordinate EMC and safety testing through trusted third-party test houses, ensuring full compliance with industry standards. Additionally, we offer some in-house pre-compliance exploratory testing to identify potential issues early, reducing risk and accelerating certification.

By choosing our testing services, you gain confidence that your products are ready for market, compliant with industry standards, and built to last.

Why is Testing so important

Testing helps identify defects early in the design and manufacturing processes, reducing costs and improving product reliability. Testing is essential for ensuring that devices operate as intended and meet user expectations.